Rev-Limit-Automotive

Topic: C5 Corvette Elitrical

">

">

">

">

">

">

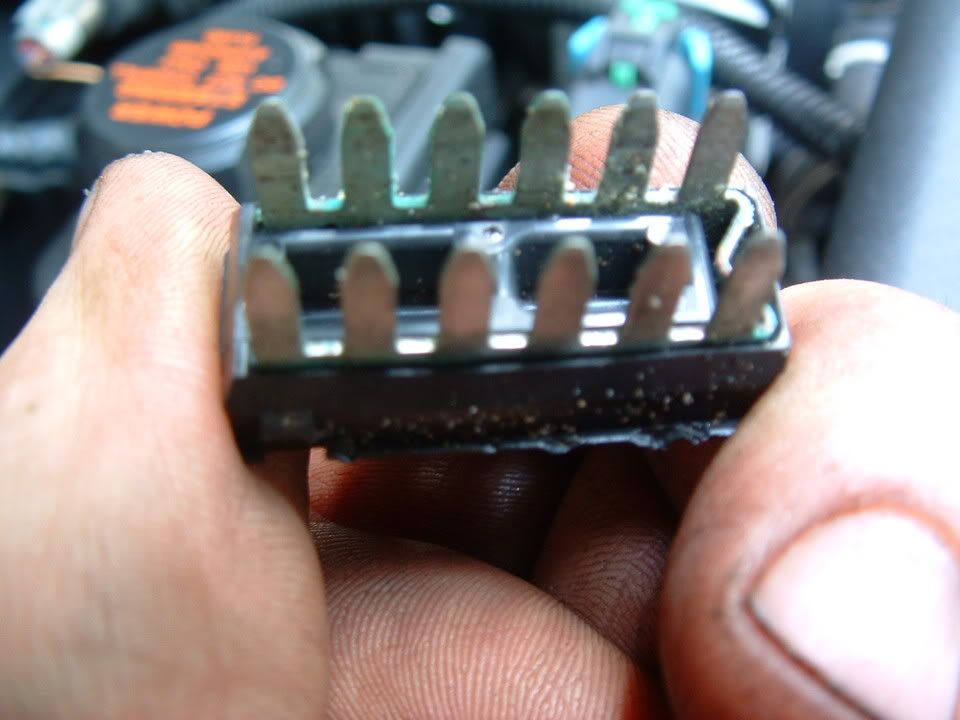

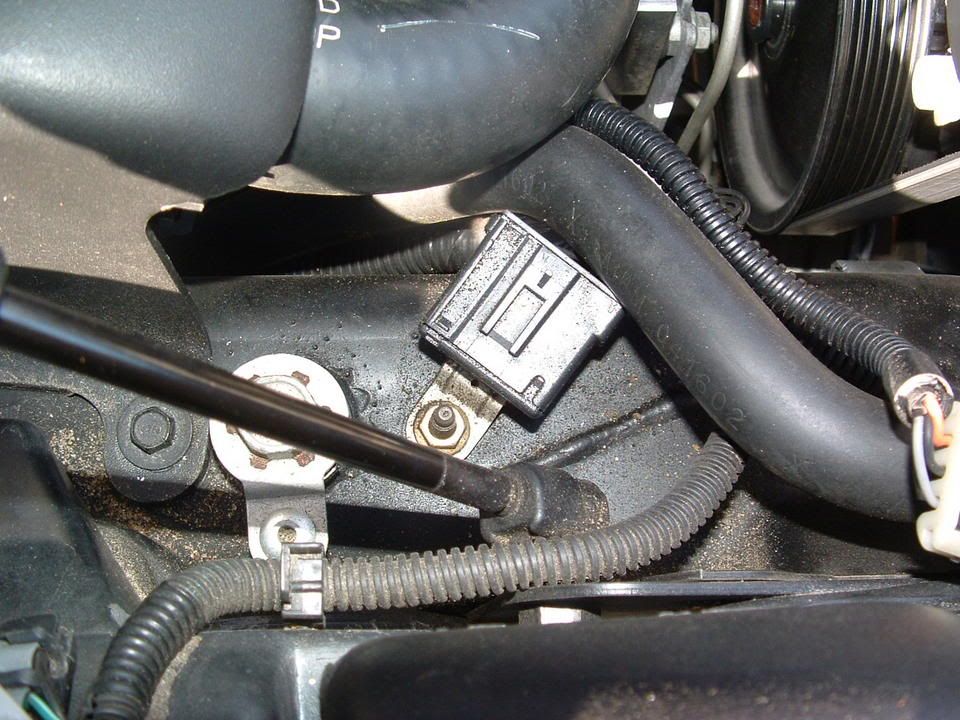

Self tapping ground screw and star washer. This is what you will need if the ground stud breaks off during removal!

"> [IMG][IMG]

"> [IMG][IMG]

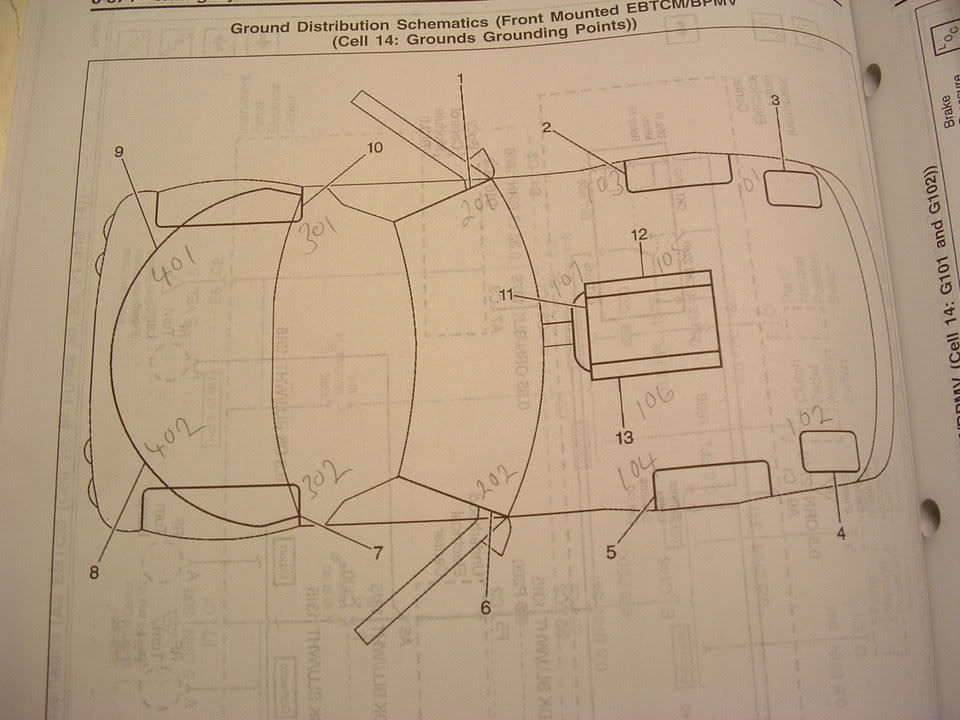

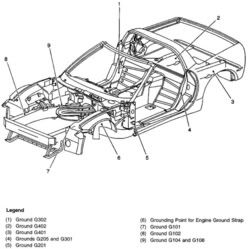

Here are where the chassis ground points are on a C5:

| This image has been resized. Click this bar to view the full image. The original image is sized 960x720. |

| This image has been resized. Click this bar to view the full image. The original image is sized 960x720. |

Page 1 of 1 sorted by

">

">